Lubricators

Lubricator Function:

Air line lubricators are designed to introduce atomized oil into the air line so that downstream mechanisms can be adequately lubricated. Lubricators should be adjusted so that the minimum amount of oil to lubricate the equipment is used. Excess oil will simply be blown into the atmosphere and pollute the environment.

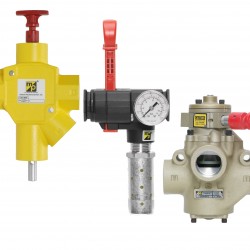

There are two basic designs used in Master Pneumatic lubricators: sight-feed design and wick-feed design. Illustrations of these two types of assembly are shown on the facing page.

Sight-Feed Lubricators:

Air flows through a flexible-vane automatic flow sensor that creates a small pressure differential between the air passage and the oil reservoir. This differential causes oil to move up a riser tube, through an adjustable metering valve, and then to drip into a transparent dome and the air stream. This oil is “atomized” by the air stream, and carried down the air line to the points of lubrication.

Sight-feed lubricators are easy to adjust, and an indicator on the sight dome measures the amount of oil dispensed. The adjusting knob can be removed to make the lubricator “tamper-resistant.”

Wick-Feed Lubricators:

In a wick-feed lubricator one end of a porous bronze wick is saturated with oil in the reservoir. Capillary action causes the oil to travel up the wick. Oil is stripped off the upper portion of the wick by the air fl ow, and maintains a constant oil-to-air ratio. This ratio can be varied by manual adjustment. Units will not shut off, even with dirt and moisture in the reservoir. However, air must be shut off when filling the reservoirs of these models.