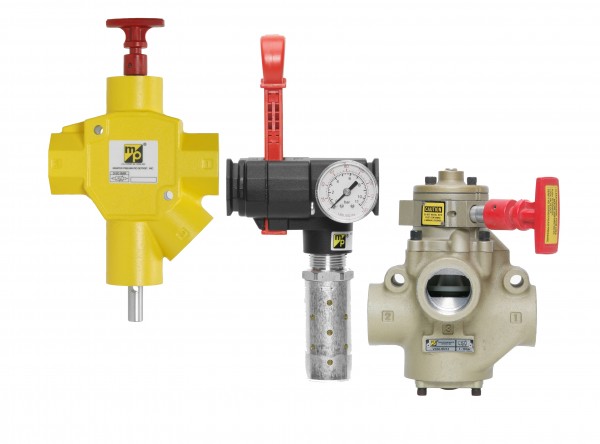

Product Accessories & Valves

In short, each piece of equipment must have a shutoff valve to isolate the equipment from its air supply. The shutoff valve must be lockable in the closed position so that it cannot inadvertently be opened. When closed the shutoff valve must have an exhaust port to exhaust downstream pressurized air.

Lockout valves are offered in a full range of port sizes, and with different actuation modes. Each valve is designed to satisfy the OSHA requirements for energy isolation and lockout. They are not, however, intended as emergency stop devices. They lock out the supply air in a system with an easy pushing or sliding motion, and also exhaust down stream air pressure. Even after extended periods on standby, the valves are designed with seals and materials that allow the lockout control to move smoothly into the lockout position. All Master Pneumatic lockout valves can be secured in the closed position by means of a padlock so that the valve cannot be inadvertently opened to cause a potentially hazardous situation. Shown above is one of the manual lockout valves padlocked in the closed position.